Heavy Equipment Rental Benefits

Renting construction equipment has increased in popularity for a variety of reasons. A few key contributors to the growth of equipment rentals include the rising cost of purchasing equipment Here are some benefits that your company will see if you decide to begin renting construction equipment.

Avoid the Initial Purchase Cost

Purchasing brand new construction equipment is extremely expensive and can make a huge impact on how your company’s budget. Renting or leasing equipment avoids the upfront costs associated with purchasing, and allows businesses to better manage your financial resources.

Less Maintenance and Repair Costs

When you own equipment, you must consider the cost of maintenance and repair. Although maintenance and repair is still important for rental equipment, costs will be lowered compared to purchased equipment. With rentals, the time and labor costs associated with maintenance and repairs are lower and more manageable.

No More Market Fluctuation

The construction world is dynamic and many things influence the market. Renting equipment cushions your company from unpredictable downturns that may arise. Rather than committing to a piece of equipment, leasing allows for options that make it easier to ride the rise and fall of market forces.

No Depreciation Costs

When you own machinery, you incur considerable depreciation costs. Reselling equipment, and maintaining it requires quite a large investment on top of your upfront purchase. Although all companies operate differently, renting construction equipment avoids loses associated with depreciation.

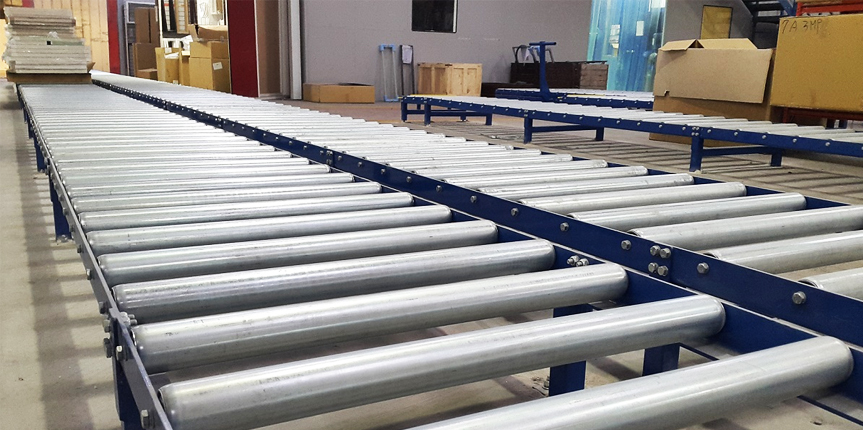

Project-Specific Rentals

Typically, construction companies are balancing many projects at once. Renting specific pieces of equipment for particular projects eliminates any logistical delays.

Solve Storage Issues

Equipment that is not stored properly, or exposed to harsh weather condition may depreciate faster. You can negotiate with vendors or suppliers regarding how long you need a rental, and your company may not worry about long-term storage. This saves you time needed to plan out the logistics, as well as the cost of storage.

Transportation Logistics

Transportation can take a long time, affecting the productivity and efficiency of a project. Renting allows you to avoid this burden and provides a more reliable equipment option by keeping pieces onsite.

Let us give you all the information you need to run on any budget and still get the equipment you need!